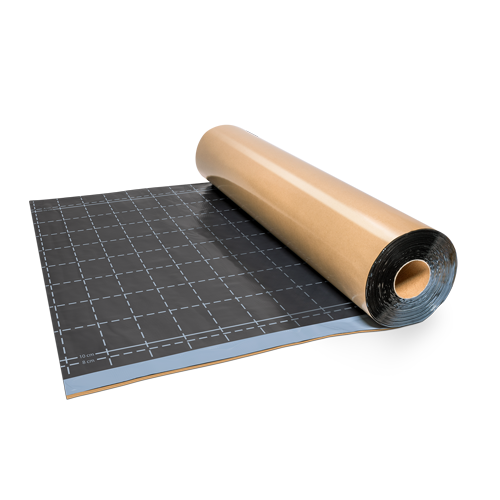

Rasco SAM with Vulcanisation Strip (Thickness 1.5 mm)

Cold-applied self-adhesive bituminous sealing membrane for waterproofing of structures in accordance with DIN 18533, EN 13969, DIN V 20000-202 and for use as a dampproof course in accordance with EN 14967

The 25 mm vulcanisation strip consists if pure bitumen compound. The purpose is to achieve better joints between the materials by sticking compound on to compound and so ensuring even better sealing.

Protects underground structures according to DIN 18533 part 2 permanently against W1-E (ground damp and pressure-free water) and W4-E (splash water and ground damp at wall base) and can be used as dampproof course below screeds. It can also be applied to balconies, loggias and pergolas in accordance with DIN 18531 part 5.

It can be applied to vertical and horizontal surfaces, foundation slabs, foundations and cellar walls. Can be used on all known and suitable mineral substrates.

Contact request

Features

- Solvent-free and environmentally friendly

- Self-adhesive, flexible, crack-bridging

- Applicable all year round

- Clean, easy and fast use

- Immediate resistance to water and driving rain

- As dampproof course below screed

- No drying time needed

- Impervious to radon

- 25 mm vulcanisation strip for secure adhesion of seams

- Polymerised bitumen on cross-laminated, tearproof HDPE carrier film with grid

- Frost-free at least 12 months shelf-life

Technical Data

- Thickness: 1.5 mm

- Width: 1,000 mm (975 mm + 25 mm vulcanisation strip)

- Weight: 1.5 kg/m²

- Water vapour permeability: Sd-value 235 m

- Resistance to hydrostatic pressure*: 8 bar (80 m) passed

- Reaction to fire: Class E

- Working temperature**: -5°C to +30°C

Packaging Unit

- 20 rm / carton | 15 cartons / pallet | pallet weight approx. 550 kg

- 15 rm / carton | 15 cartons / pallet | pallet weight approx. 430 kg

- 5 rm / carton | 24 cartons / pallet | pallet weight approx. 250 kg

* Examination was carried out using a test unit from company “Form+Test Seidner” type “DP 3 MM”. High pressure load testing was carried out over a period of 5

days. No connection to actual circumstances and requirements on the building site exists.

** Temperature: component, installation and ambient temperature.

Contact

Technical Service

+49 5237 608-119 oder

+49 5237 608-138

awt@bitumentechnik.de

Sales

+49 5237 608-139

vtrasco@bitumentechnik.de

Contact request